Artificial intelligence (AI) might sound like something from the future, but it’s already hard at work in factories all over the world. From streamlining production lines to predicting equipment failures before they happen, AI is changing how we make things—making the process faster, smarter, and more adaptable than ever before.

Let’s take a closer look at how AI is being used in manufacturing today, and why it’s such disruptor for the industry.

What Does AI in Manufacturing Actually Look Like?

At its core, AI helps machines and systems make decisions based on data—kind of like a super-smart assistant that never sleeps. Manufacturing is full of data: sensor readings from machines, production statistics, inventory levels, energy usage, and more. AI takes all that data and turns it into something useful.

For example, machine learning (a key branch of AI) can analyze patterns in data to predict when a machine might fail. Instead of waiting for something to break and cause a delay, companies can fix issues before they become problems. That’s predictive maintenance—and it’s saving manufacturers time and money.

Another area where AI shines is quality control. Traditional inspections can be time-consuming and inconsistent, but AI-powered computer vision systems can scan products on the line in real-time, catching even the tiniest defects faster and more accurately than the human eye.

Generative AI: More Than Just Chatbots

You’ve probably heard about generative AI (or “gen AI”)—tools that create text, images, or even code based on past data. In manufacturing, gen AI has much more to offer than drafting emails.

Engineers are now using generative AI for design and prototyping. Imagine giving the AI a set of parameters—like material type, weight limits, and size restrictions—and getting back dozens of design ideas in minutes. It’s like having a creative brainstorming partner that never runs out of ideas.

Gen AI also helps with customer service, document summarization, product searches, and even writing instructions or maintenance schedules. It’s proving especially useful in managing complex supply chains by simulating different scenarios and helping teams make better, faster decisions.

Welcome to the Smart Factory

The term “smart factory” is often thrown around, but what does it really mean? Essentially, it’s a manufacturing setup where machines, systems, and people are all connected through the Internet of Things (IoT) and powered by real-time data analytics and AI.

In a smart factory, AI doesn’t just monitor what’s happening—it actively makes adjustments. If a sensor detects an issue on the line, AI can reconfigure production or redirect materials, keeping everything running smoothly without human intervention. The result is maximum efficiency, less waste, and faster production times.

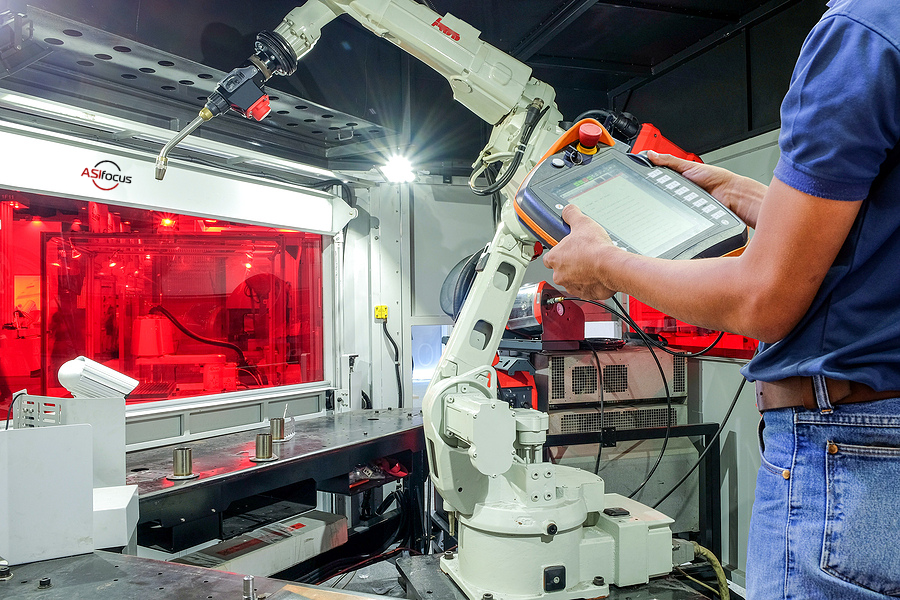

Working Side-by-Side with Robots

One of the coolest innovations in AI-powered manufacturing is the rise of collaborative robots—also known as “cobots.” Unlike traditional industrial robots that operate behind safety barriers, cobots are designed to work safely alongside humans.

Cobots handle repetitive or physically demanding tasks, freeing up human workers to focus on more complex, creative, or supervisory roles. Think of it as teamwork—where robots and people complement each other’s strengths.

Real-World Applications: AI in Action

AI is being used in so many different ways across the manufacturing process. Here are a few real-life examples:

- Digital twins: AI helps create virtual replicas of production lines, machines, or even entire factories. These “digital twins” let teams simulate and test changes before rolling them out in the real world.

- Custom manufacturing: Want to offer personalized products without slowing down production? AI can make that happen, adjusting manufacturing processes in real-time to meet individual customer needs.

- Factory-in-a-box: Using modular, AI-powered manufacturing units, companies can now “pop up” mini-factories in new locations quickly and cost-effectively.

- Energy management: AI can monitor a factory’s energy use and spot inefficiencies—leading to big savings and a smaller carbon footprint.

- Inventory optimization: By analyzing sales trends and supplier data, AI ensures the right parts and products are in stock at the right time, reducing overstock or costly shortages.

AI Isn’t Just for the Factory Floor

Generative AI is also streamlining the tasks that support manufacturing behind the scenes. Things like ticket and call handling, market research, or writing technical documentation can all be automated or assisted by AI tools.

Need to find a specific product but don’t know the exact name or code? AI-powered search can help. Want a quick summary of a 20-page document? Gen AI can pull out the highlights for you in seconds. These tools save time and reduce the mental load on workers, letting them focus on higher-value tasks.

The Big Picture: Why AI Matters in Manufacturing

So, what’s the bottom line? Here are some of the biggest benefits AI brings to manufacturing:

- More efficiency: AI automates routine tasks, streamlines workflows, and helps machines run smoother—boosting output without extra labor.

- Cost savings: With better maintenance planning, less downtime, and optimized energy use, companies are saving real money.

- Smarter decisions: AI delivers insights in real-time, helping managers respond to changes on the fly and make better long-term plans.

- Safer workplaces: Cobots and smart systems reduce human exposure to dangerous or physically demanding work.

- More sustainable practices: By cutting waste and optimizing resource use, AI supports greener, more responsible manufacturing.

- Faster innovation: With tools like generative design and digital twins, companies can experiment, prototype, and adapt faster—keeping them ahead of the competition.

Our Thoughts on AI in Manufacturing

AI is no longer a futuristic concept—it’s a practical, powerful tool that’s already reshaping how we manufacture everything from cars to electronics. By improving efficiency, enabling smarter decisions, and creating more adaptive systems, AI is helping manufacturers build better products faster and more sustainably.

Whether it’s on the factory floor or behind the scenes, AI is proving to be a vital partner in the push toward a smarter, more innovative future.

If you have any questions or want help, we’re here to chat. Feel free to contact us or schedule your free consultation.