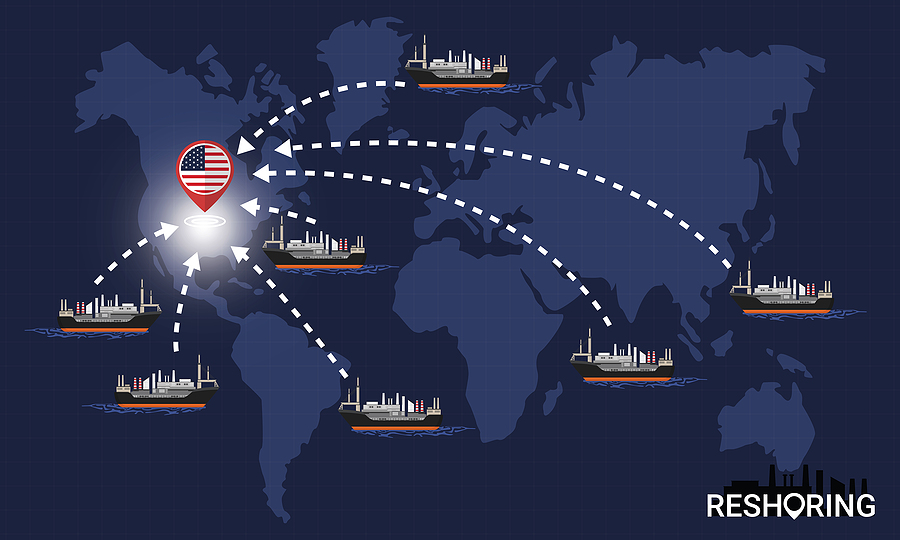

It is no secret that US manufacturers have long relied on foreign labor to produce their products. Still, with increasing concerns over security and supply chain issues, cheap foreign labor is no longer the most viable option, particularly for manufacturers of high-end products with a substantial profit margin. These companies must increasingly consider reshoring their production, but even this is not without challenges.

Labor Shortages

The US has been experiencing a labor shortage in recent years thanks to pandemic-related business closings. As of October 2022, there were around 6 million unemployed workers to fill about 10 million US jobs.

Companies that must reshore their operations find it challenging to find workers to get the job done, and those they do find may not have the needed skills. This means spending money on training, but the cost goes beyond just getting suitable employees.

The labor shortage also makes creating the needed infrastructure for US-based manufacturing difficult. After years and years of sending labor overseas, suitable manufacturing facilities do not always exist. This does not just require workers to build the infrastructure; it takes time that many companies do not have.

Power and Transportation Costs

Infrastructure is not just about a suitable facility; it also involves the power grid. Some parts of the country just do not have a power grid that can sustain the needs of heavy manufacturing. While one area may not have a grid with enough capacity, other areas with enough capacity may already have reached the limit of how many manufacturers it can sustain.

Then there is the cost of transporting materials to new facilities. In the struggle to find the right location for a new manufacturing facility, finding one with local vendors can be tricky. All these factors mean higher production costs overall.

Community Opposition

Without public support, opening a new manufacturing facility is a huge challenge. A company may not be able to get the necessary permits to build if residents do not want a factory in the neighborhood. And with an already overabundance of jobs available, bringing jobs to the area is not the incentive it used to be.

If reshoring is part of your company’s trajectory, be ready for a challenge. As with most challenges, however, there is also opportunity.