The importance of quality control in manufacturing cannot be overstated if your company produces multiple daily units of your product. Your scrap rate will increase if your processes cause a product defect. A quality control program needs to be implemented to resolve these issues.

Best Practices in Manufacturing Quality Control

Your team will be able to identify and correct errors by using these five quality control best practices.

1. Have a Plan

If your team doesn’t have a quality control plan, it doesn’t know how the company will ensure its products meet quality and customer expectations.

- Here are suggestions on what to include in your quality control plan:

- Your objectives for quality control

- Defining the company’s quality standards

- Requirements to reach company standards

- Procedures used to verify compliance with the required criteria

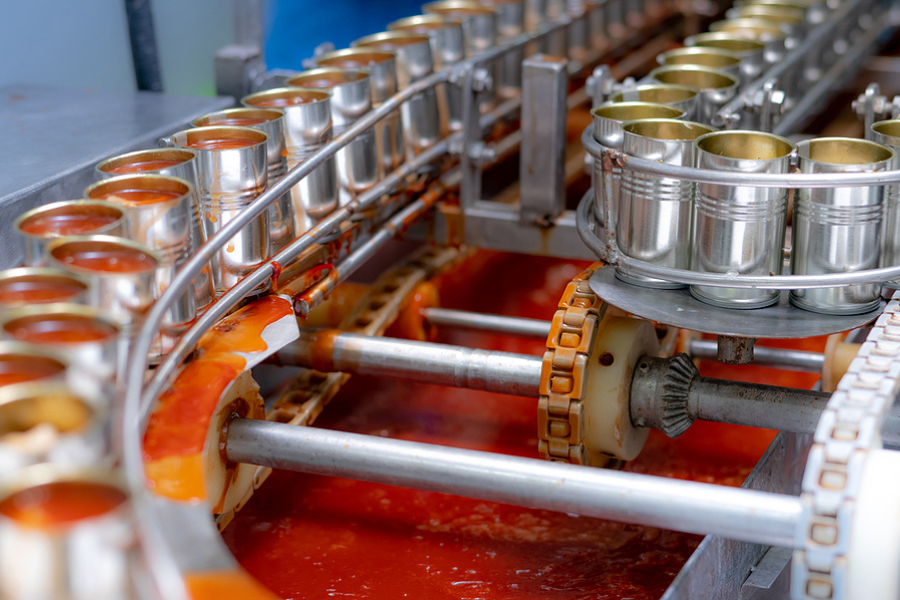

2. Streamline Your Facility’s Operations

Your company can produce higher-quality products more quickly and economically by automating its manufacturing facilities.

The following are some ways that automation improves product quality:

The Human Error Factor Is Eliminated: With automated systems, errors caused by human error are eliminated.

Increases Accuracy: Many products require precise measurements and placements during the manufacturing process. By automating your company’s machines, you ensure consistency in results.

Automation provides more visibility: Triggers and sensors monitor your company’s machines in real-time to highlight any malfunctions or defects early.

3. Analyze Each Batch of Product Samples

Your team can confirm quality during various production stages by regularly inspecting products. A thorough inspection should include examining, measuring, gauging, or testing the product. It is necessary to compare the results with a set of requirements.

Inspecting raw materials and components both during and after production is vital. Your team should regularly examine partially produced products to identify potential defects more efficiently.

4. Maintain a Complete Record of Your Production Processes

Keeping records is crucial to manufacturing quality control. An effective manufacturing quality control system will allow you to track all steps in your production process, thus allowing your company to report more quickly.

By keeping records of your processes, your team will be able to:

- Monitoring the performance of suppliers

- Identify patterns

- Optimize production run scheduling

- Identify and resolve product quality issues

- Provide better customer service

This will result in a reduction in downtime, product defects, and waste generation.

5. Improve Quality by Reviewing Your Findings

Analyze the findings and develop an improvement plan. You should reevaluate your processes and products after analyzing the information collected. Your team must keep compliance and applicable regulations in mind during this process.

Next, repeat the process. A higher-quality product is produced every time a manufacturing quality control cycle is conducted. As a result, your customers are happier, fewer products are returned, and your company makes more money.

Experience the Business Benefits

If you’re ready to experience the benefits of manufacturing quality control in your business, we can customize a solution to help you meet your needs and reach your goals. To learn more and get your customized recommendations, contact us today.