Industrial robots have been part of warehouse automation since 1956, when large robotic arms could move material approximately 12 feet. Other robots have been designed only for industrial manufacturing, considered unsafe for humans to be around while in use. Today, warehouses feature small robotics that can do everything from moving material across entire warehouses to sorting a variety of products. Robotics and automation could very well be what drive Industry 5.0.

Still, there is valid concern from the human workforce. The warehouse industry currently employs more than 1.1 million Americans, but robotics aren’t here to steal jobs. Instead, adding warehouse automation can enhance productivity.

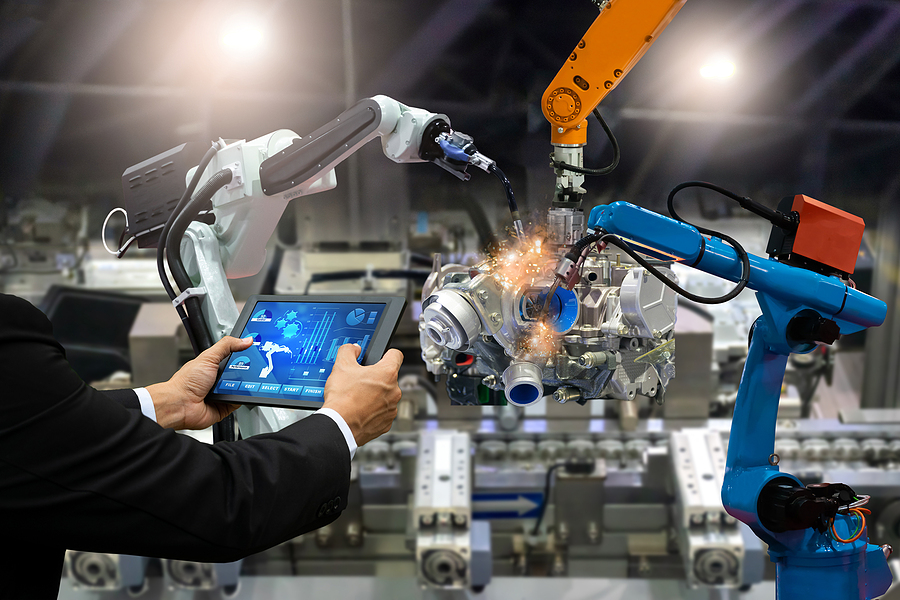

Robotics in Warehouse Automation

Automation makes the most sense in warehouses, where repetitive actions are the norm. Rather than positioning robots and automation as competition for jobs, leadership should ensure new robots are collaborative instead. Collaborative robots function as a flexible automation solution, bridging the gap between operational staff, existing equipment, and data systems.

Here are a few ways automated robots are already changing the face of warehousing:

- Optimized Resource Management and Flexibility: It’s often necessary to adjust your warehouse’s capabilities to accommodate demand. Rather than executing a costly solution such as changing the warehouse layout or using alternate shifts, you can easily retrofit robots into new warehouse layouts. Some robotics providers also offer rentals so you can easily scale up and down to meet current capacity.

- Increased Warehouse Productivity: While there may be 1.1 million Americans employed in warehouses, the number of qualified warehouse workers is decreasing, leading to staffing challenges. Adding collaborative robots can increase productivity two to three times without adding undue stress on current employees.

- Real-Time, Data-Driven Decisions: By leveraging machine learning, collaborative robots can easily “learn” how to make data-driven decisions in real time. Based on data findings, a robot can empower human colleagues to handle multiple tasks during one walking trip on the floor, accomplishing more in less time while also protecting the level of wear and tear on the human body from hard concrete floors.

- Increased Reliability: Robotics don’t need sick days like their human colleagues, but breakdowns can occur, leaving a robotic “employee” dead weight. With robots’ portability and serviceability, it’s easy to move another robot into play while repairs are made, allowing the warehouse to continue on with little to no downtime.

Helping Humans and Robots Work Together

While it’s easy to fear the unknown, electronic “colleagues” should be seen not as competition, but as profound development for saving time so people can spend time on more productive tasks. Uniquely human aspects such as imagination, creativity, curiosity, and emotional and social intelligence are things machines will never have. Instead, focusing robotics on the menial tasks frees our minds for specifically human work that will be on the rise as people continue to push for products and services that will empower us to achieve more.

The transition to warehouse automation and robotics may be painful in the short term due to real fears of human job loss. Yet it will still take human touch to understand both emotional context and perform creative problem-solving. Reframing how robotics work with human colleagues and committing to upskilling employees for the tasks robots cannot handle will make this transformation period less painful.

Prepare for Warehouse Automation With ASI

Adding robotics and automation will create a veritable landslide of data from your warehouse. Tracking that data and making use of it requires having the right ERP and other business software solutions purpose-built for your warehouse and manufacturing business. The software you choose today can determine the success of your warehouse automation and robotic “colleagues” in the future. Find exactly what you need with help from ASI. Contact our software experts now.